Establish a remote monitoring platform for equipment to record real-time equipment operational data, enabling quick detection of equipment malfunctions and carrying out after-sales service in time.

Customers' factories need informatization and solution for large quantities of PLCs. Flexem's HMI, with its tag communication functionality, can facilitate collaborative development by multiple users and conveniently materialize factory informatization, allowing the transmission of underlying data to upper-level software.

The processing stage of photovoltaic equipment is relatively complex, with high requirements for integration with MES and other software. Flexem's HMI, with its tag communication functionality, can resolve extensive data computation challenges, enable modular programming for complex processes, and facilitate integration with MES.

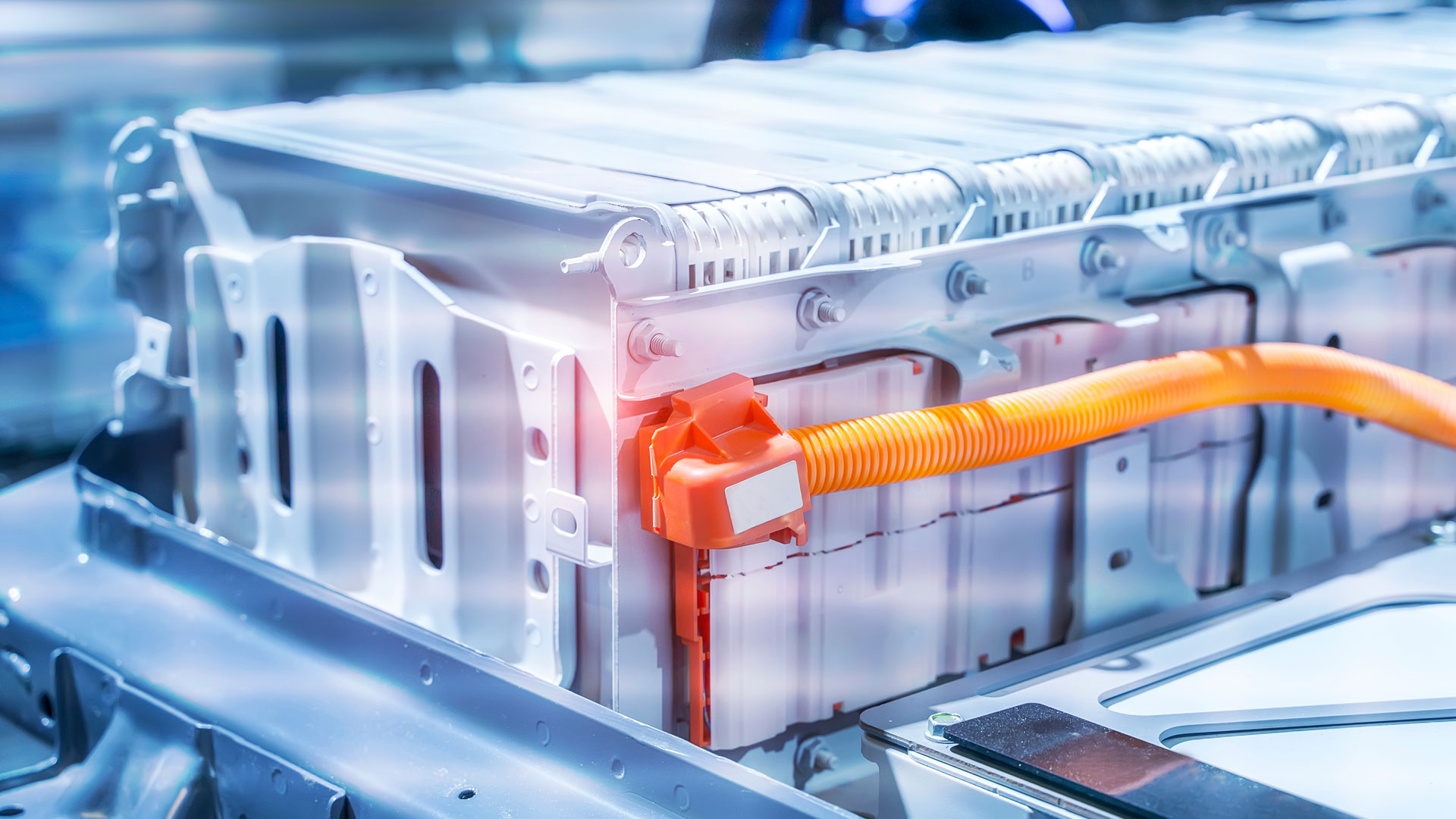

Lithium battery equipment comprises a large quantity, requiring easy debugging procedures, high standardization, and a significant number of repetitive modules. Flexem's products can facilitate lithium battery manufacturers to achieve engineering standardization, modular programming, multi-screen debugging, and integration with MES.

To provide a comprehensive remote equipment monitoring solution for the air conditioning industry, FBox can connect to PLCs and controllers on-site, wireless transmit equipment data to the remote cloud server through the wireless network, and achieve equipment remote management and maintenance through the monitoring platform.